Take a close look at the scat tubing that runs to the oil cooler. Paul installed a control device that regulates air through the cooler to control oil temps. As you can see, the rest of the engine compartment is just as sanitary!

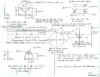

Paul recently drew up plans for his heater control door. While Paul hasn't had any oil temp problems this winter he's holding off judgment until the hotter weather arrives. Click the picture at left to see the drawings.

UPDATE 07/ 2001 Paul reports that even on 90+ degree days oil temps are staying well under 210 degrees. It would appear that the remote mounted oil cooler, oil cooler door and scat tubing are working great.

The second drawing shows how to make the shaft the butterfly attaches to.

Look at these drawings would you? CAD stuff is nice but there is nothing like a professional blueprints done by hand. Each one has it's own personality.

Notice the clear coat paint job. The pictures do not do it justice, but this is one immaculate paint job. It is glass smooth and deep looking.

Paul's -6 uses an O-320 and C/S prop. Not seen in this picture is a unique defrost system. At the bottom of the inside windshield, Paul built a fiberglass lip and cut slots every few inches. If necessary, Paul can route the cabin heat to this area to defrost the windshield.

Paul has matching wheel pants ready but will leave them off for the first flights.

Paul has also installed some sheepskin seat covers and they look great. As soon as he gets his hours flown off I'll get a chance to sit in those things and check them out. The baggage compartment cover is also a nice touch to help give the plane an overall professional appearance.

Paul had a need for a gust lock and didn't find anything he liked that was simple and easy to use......so he designed his own. They don't get much simpler or easier to use. It stores in his map pocket and I can attest, the control surfaces WILL NOT MOVE when this simple device is in place.

The pictures pretty much tell the story. There are two holes drill in the flange at the bottom of the instrument panel and that's where the end of the control lock slides in. In effect, the instrument panel is keeping the stick from moving.

The control lock is made from an old fashioned coat hanger.

The insulation layer is

in place and the spruce strips for attaching the

plywood are screwed to the side of the Al. angle

supporting the floor. There is also one Al.

angle clip with a tapped hole located at the mid

point of the battery.

This shot shows the support strips mounted to the bottom of the plywood at the outboard side. The plywood is held down because it fits both under and over the corner Al. angle.